Mercedes says that its new four-cylinder OM 654 diesel engine will ensure the diesel is “future proof” while helping the firm to achieve “challenging global climate targets”.

Leaving aside the fact that no technology in history has ever turned out to be future proof, this does seem to be an impressive new engine.

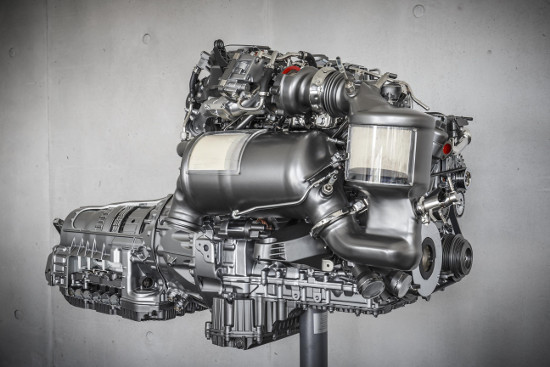

Made from aluminium, this four cylinder , two-litre engine will make its debut in the E-Class E 200d later this year, but will eventually be used across the firm’s range of cars and vans. There are plans for several output variants as well as longitudinal and transverse installation in vehicles with front-, rear- and all-wheel drive.

The new engine replaces the current 2.1-litre model and is the first all-aluminium four-cylinder diesel engine. Despite its lower capacity it promises to deliver and increase of power from 125kW to 143kW. Fuel consumption and CO2 emissions should both fall by around 13%.

One of the big challenges with diesel engines in recent years has been managing the more noxious emissions produced by these engines. Two stages of exhaust treatment are required to meet Euro 6 standards, EGR (Exhaust Gas Recirculation) and SCR (Selective Catalytic Reduction, which is what AdBlue is used for).

Unlike existing Euro 6 models, the new engine will include all of this exhaust treatment technology. Until now, this has tended to be bolted on, rather than built in. Mercedes says that this will improve fuel efficiency on short journeys and remove problems related to temperature management during cold starting — exhaust treatment systems such as catalysers generally only work properly when they have warmed up.

In fact, the exhaust gases will receive nearly all of the necessary pollution control treatment before they leave the engine, as Mercedes explains:

The exhaust gas from the turbocharger is sent first to a diesel oxidation catalyst. It next passes the downdraft mixer, in which AdBlue is added by means of a water-cooled dosing module.

Thanks to a specially developed mixing area, the AdBlue evaporates over the shortest possible distance in the exhaust gas stream and is distributed very uniformly on the surface of the downstream sDPF (particulate filter with coating to reduce nitrogen oxides).

Positioned behind the sDPF is an SCR catalyst for further catalytic reduction of the nitrogen oxides. Only then does the treated exhaust gas enter the exhaust system.

I’m not sure I’d fancy owning something this complicated when it starts to get old, but this integrated setup does sound like a worthwhile improvement on the current crop of diesel engines.